Introduction

Automotive oil cooler is a compact heat exchanger designed to cool down the oil circulating within the engine, transmission, or other vehicle components. Since oil absorbs a significant amount of heat during operation, especially under high-performance or heavy-duty conditions, this device helps dissipate excess heat to maintain the oil within its optimal temperature range.

Key Function: Keeps oil temperature stable, ensuring efficient lubrication, preventing thermal breakdown of oil, and safeguarding engine and transmission parts from excessive wear.

Types of Automotive Oil Coolers

Air-Cooled Oil Coolers

- Use ambient airflow, typically directed by vehicle motion or an auxiliary fan.

- Equipped with finned tubes or plates to maximize surface area and heat dissipation.

- Common in: Racing cars, older diesel engines, and aftermarket performance applications.

Water-Cooled (Oil-to-Water) Coolers

- Use the vehicle’s coolant system as the heat sink.

- Compact and efficient, often integrated within the engine block or oil filter housing.

- Common in: Modern passenger vehicles, luxury sedans, and hybrid cars.

Stacked Plate Oil Coolers

- Constructed from a series of stacked plates that oil flows through.

- Provides a large surface area for heat transfer within a compact size.

- High durability and performance efficiency.

- Common in: Sports cars and racing applications.

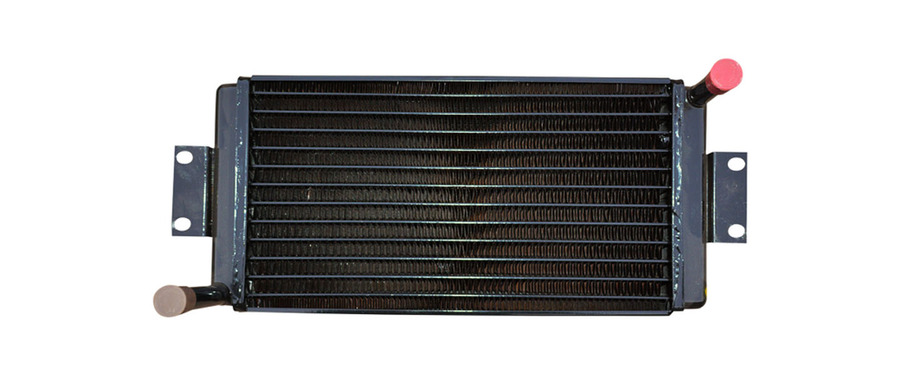

Tube & Fin Oil Coolers

- Composed of coiled or straight tubes surrounded by cooling fins.

- Simple, lightweight, and economical design.

- Common in: Passenger cars, small SUVs, and motorcycles.

Bar & Plate Oil Coolers

- Uses a robust bar and plate core construction.

- Superior strength and cooling capacity.

- Heavier but ideal for extreme conditions like off-roading and motorsport.

- Common in: Heavy-duty trucks, military vehicles, and track cars.

Unique and Lesser-Discussed Details

Thermal Expansion Management

Oil expands significantly when heated, and poor management can lead to pressure build-up, causing leaks or component failure.

High-end coolers like bar & plate models incorporate expansion plates or flexible joints that accommodate this expansion and contraction, especially crucial in track or desert conditions where oil temperature fluctuations are aggressive.

Integration in Hybrid & EV Powertrains

Though EVs don’t use engine oil, they rely heavily on gearbox and inverter oil cooling. These components heat up rapidly under high torque and regenerative braking.

Specialized oil coolers are now being added for:

- Power electronics cooling

- Reduction gear lubrication

- Battery thermal management via oil-based systems

Example: Porsche Taycan and Tesla Model S Plaid feature dedicated oil coolers for drive units.

Oil Cooler Thermostat

In cold conditions, cooling the oil too much is harmful as it thickens, reducing flow and protection.

Solution: Many systems now integrate a thermostat-controlled bypass which routes oil through the cooler only when it surpasses a preset temperature (typically 80-100°C).

Benefits:

- Faster engine warm-up

- Prevents overcooling

- Maintains oil pressure stability

Detachable/Serviceable Designs

High-performance or off-road vehicles often experience oil cooler clogging due to dirt, dust, or metal shavings.

Advanced systems feature:

- Removable cores or tube bundles

- Easy access for cleaning, descaling, or tube replacement

This extends service life and improves reliability for vehicles operating in harsh environments.

Dual-Purpose Coolers

Modern vehicles aim to save weight and space. One way is using multi-circuit coolers that handle both engine oil and transmission oil through independent channels within a single unit.

Advantages:

- Compact design

- Lower installation complexity

- Improved overall thermal efficiency

Used in: High-end SUVs, sports sedans, and performance trucks.

Summary Table of Automotive Oil Cooler Types

| Type | Cooling Method | Applications | Key Benefit |

|---|---|---|---|

| Air-Cooled | Ambient air | Performance cars, classic vehicles | Simple, efficient, economical |

| Water-Cooled (Oil-to-Water) | Engine coolant | Modern sedans, hybrid vehicles | Compact, uses existing cooling loop |

| Stacked Plate | Air or water | Racing, high-performance vehicles | High heat transfer in small size |

| Tube & Fin | Air | Passenger cars, motorcycles | Lightweight, low cost |

| Bar & Plate | Air | Off-road, military, track cars | Heavy-duty, highly durable |

Conclusion

Automotive oil coolers play a vital role in maintaining the health and performance of modern vehicles, especially under demanding conditions. By efficiently regulating oil temperatures, they preserve the oil’s lubricating properties, protect vital components, and enhance overall engine and transmission longevity. With a wide range of types — from compact tube & fin designs to heavy-duty bar & plate coolers — these systems can be tailored to suit everyday driving, racing, off-road adventures, or commercial applications. The rise of hybrid and electric vehicles has also expanded the scope of oil cooling, with specialized systems now managing temperatures in power electronics and gear units.