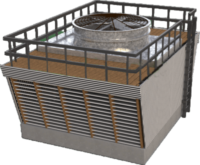

FANLESS COOLING TOWER

Wooden cooling tower design incorporates accommodation of waters with very high TDS factors the hot water from the source when circulated to the gathering basin with flower pot nozzles, are sprayed over the fill space. at the same time, air is induced through the fill media therefore eliminating the heat energy from the water passing through the fill media. Parts of water gaseous, removes the heat from the remaining water. The warm wet air is drawn through the fan deck is discharged to the atmosphere. Cold water, collected at the collection sump, is re-circulated to the heat supply.

KEY CHARACTERISTICS

| DRAUGHT TYPE/ MATERIAL | FLOW TYPE | MOC | WATER FLOW RATE (m3/hr) | FILL TYPE | DRIVE TYPE |

|---|---|---|---|---|---|

| Induced / Wooden | Cross Flow | FRP | 180 – 2640 | Wooden Fills | Direct, Gear Reducer |

| Louvers | FRP (Isopthalic with Gel Coating) |

| Structural Supports | FRP (Isopthalic Resin with Gel Coating and MS Inserts) |

| Inlet Flanges | Heavy Duty PVC/PP |

| Spray Header | Heavy Duty PVC/PP , 10Kg/cm2 pressure rating(FRP Lined) |

| Drift Eliminators | FRP (Inbuilt in Louvers) |

| Spray Nozzles | 30% Glass Filled Nylon 6 |

| Nut, Bolts & Washers | 30% Glass Filled Nylon 6 and MS Inserts |

- The Structure is made of timber with hardware in options of MS/HDG or Stainless steel.

- Timber is an organic , non-polluting and naturally occurring renewable building material ensuring the timber-cooling tower is as environmentally friendly as it can get.

- The timber is chemically treated with IS-401 to protect the structure from decay and attack by termites and other micro-organisms.

- These types of cooling towers are cost effectiveness and economic life cycle.

PARTS/COMPONENTS

FAN ASSEMBLY:

Induced draft axial type fan assembly with pitch adjustable fan blades. Fan blades material could be FRP Aluminium extrusion or Aluminium alloy. Fan hub material is H.D.G.Steel.

ELECTRICAL FAN MOTOR:

Electrical Fan Motor Is Specially Designed for Cooling Tower Application .It Has Low Rpm, Long Shaft Fitment and Vertical Mounted For Better Airflow, Reducing Vibration and Low Noise Pollution. Test [Total Enclosed Surface Cooled] Insulated Ip-55 Grade With Weather Proof Design Sustain In Bad Weather.

GEAR REDUCER / MOTORIZED GEARBOX :

The gearbox used for reducing the speed from the incoming motor to the outgoing fan of the cooling tower. The minimum service factor is 2.0 life of the baring is longer than the 1,00,000 hours. The gear box. Without the gearbox technology, Cooling tower motor would be massive to directly handle the torque required by the fan. The large cooling tower application ,the fan typically operates at a speed between 100 to 200 RPM. The most common RPM is 1800RPM.

DRIVE SHAFTS :

The driveshaft transmits power from the output shaft of the motor to the input shaft of the Gear reducer. Because the driveshaft operates within the tower, it must be highly corrosion resistant. Turning at full motor speed, it must be well balanced—and capable of being re-balanced. Transmitting full motor power over significant distances, it must accept tremendous torque without deformation. Subjected to long term cyclical operation, and occasional human error, it must be capable of accepting some degree of misalignment.

FAN DECK:

The Wooden Cooling Tower fan deck is horizontal surface found at the top of the tower. The fan Deck is a grade place to soak up the sun. It provides the axis to the various mechanical components of the cooling tower. Depending upon the configuration. The fan deck will be constructed of the plywood / FRP.

WATER DISTRIBUTION SYSTEMS:

Open gravity type basin made of tongue and grooved treated timber Plank / marine Plywood fitted with polypropylene spiral target nozzles to have uniform hot water Distribution over the entire fill area.

PARTS/COMPONENTS

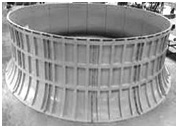

WOODEN FRAME WORK STRUCTURE

Imported Pine Woods Are Used in Casing Structures. Wood is treated for Working In Water and Bad Weather. Structure Is Covered With Asbestos Sheet or FrpSheet.

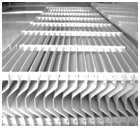

WOODEN FILLS:

We use Treated Pinewood Wooden Fills reapers or PVC V Type Splash Bar for the wooden cooling towers. As it gives the better performance to cool the water with high efficiency. The fills will work on the principle of pausing the flowing water to fall through a grid of wooden reapers fills / Splash Bar. Pausing the water droplets to break up & increase the contact time between water & Air . Also the falling water encounters, multiple layers of this splash fills. Droplets keep diving into smaller size will be increasing the heat transfer and cooling the water.

FILL SUPPORT GRID

The fill support grid is used for support the fills & the material of Fills Grid Support is SS304 and FRP. The maximize the portability of water drops continuously encountering These thin horizontal stripes on their way down the basin. This grid is non-corrosion from the Raw water. The grid are supported in uniformly spaced tiers throughout the cell Width and length on the stainless steel wire hanging from supports installed under the Water distribution systems. The each grids in each tiers is secured to all adjacent grids by special clips that tie the entire fills assembly in a secured place . We have supplied these fills support grid for all sizes of the cooling tower.

DRIFT ELIMINATOR :

The Drift Eliminator are used to capture the water droplets in the air steam that otherwise would be lose to the atmosphere. The Drift Eliminator are specially to achieve the maximum efficiency in both counter flow and cross flow cooling tower application with various product option to minimize the pressure drops.

Materials Used:Treated Pinewood, UV Resistant , U-PVC

TARGET NOZZLE:

The Target nozzle is an injection moulded polypropylene unit consisting of two parts—the main body with integral target diffuser and a Snap-On insert or orifice cap. The Spiral Target nozzle is available in three lengths. The 2.625 nozzle is used on wood, steel, and fiberglass cooling towers where basin support structure does not obstruct the release of water. The 4.875 nozzle is used on larger industrial wood and concrete cooling towers and on applications where clogging might be a concern. The 6.875 nozzle is used on towers where the release of the water has to clear obstructions within the tower structure. In every application the target portion of the nozzle should be located at the correct distance above the top of the cooling tower fill to obtain maximum water distribution over the fill area.

FLOW CONTROL VALVE :

Flow control valves have a simple & reliable design and are available in the capacity range of 300 to 2200 m3/h and size ranges of 150 to 300 NB. They are built specifically for cooling tower use and ensure low head losses. They are made of heavy duty cast iron bodies and have a stainless steel valve stem. We also coat our control valves with a layer of protective coating that resists corrosion.

WOODEN/FRP/ASBESTOS LOUVER:

The standard cladding of profile corrugated asbestos cement sheet, the joints of which are lapped to shed water only inside the cooling tower. Louvers are supported and positioned by combination tower columns and louvers supports.