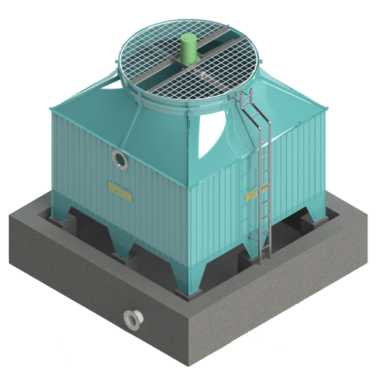

MULTICELL COOLING TOWER

“The casing and basins of the Multicell Cooling Tower are engineered to withstand severe vibrations, high wind loads, and resist corrosion. These FRP casing and basins are designed to resist severe vibrations, wind loads, and corrosion. This design enables the tower to deliver maximum cooling efficiency in a compact space while consuming less energy.”

KEY CHARACTERISTICS

- By installing multi-cell cooling tower, company can save tremendous power while receiving optimum level of performance.

- It facilitates minimum drift loss because of fully covering drift eliminators. Optimized Fan design for low power consumption, low noise & vibration.

| DRAUGHT TYPE/ SHAPE | FLOW TYPE | MOC | CAPACITY (TR) | FILL TYPE | DRIVE TYPE |

|---|---|---|---|---|---|

| Induced / Rectangle | Counter Flow | FRP | 100 – 10,000 | Honeycomb Fills | Direct, Gear or Belt |

| PARTS | MATERIAL |

|---|---|

| Casing | FRP |

| Basin Support | FRP / HDG Steel |

| Distribution Pipe | PVC/FRP/GI |

| Intake Louver | PVC / FRP |

| Fill | PVC |

| Casing | FRP |

| Nozzle | ABS / PP |

| Drift Eliminator | PVC |

| Fan Stack | FRP |

| Fan | Aluminium / FRP |

| Reducer | Gear |

| Ladder | HDG Steel |

| Fan Guard | HDG Steel |

| Motor Support | HDG Steel |

FRAME STRUCTURE

Each Protruded FRP member is pr-fabricated as per drawings and shipped to site for Ready installation. Every Column is anchored to the foundation to obtain highest Structural stability. Stainless steel fasteners are used throughout the cooling tower in conjunction with bearing sleeves to minimize fiberglass shear stress in the bolted Joints. If any member has to be replaced for any reason, its simple matter of unbolting the structure and adding the new part.

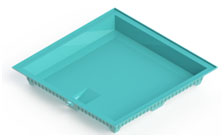

FRP BASIN

The tower casing is made of FRP featuring anti-corrosiveness, Ultra Violet resistance And weather proofing. The inspection hand hole on the tower body is convenient for Checking the distribution condition.

PVC FILLS

The fillings are made of PVC.They have excellent heat exchange efficiency & remarkably good chemical resistance. These fills are totally enclosed in the tower, thus excluding them from sunlight and minimizing the growth of algae.A pre-eminent quality and long life fill consists of modular block of PVC honey combs construction to create prolonged contact time of hot air with water for maximum heat transfer.

HEADER PIPE

The Header pipes are used for co-current water distribution systems. Air and water both travel together in the same direction from top to bottom. Hot water is allowed to spray through specially designed nylon/pp nozzles at minimum 0.5 kg./ sq. cm pressure. Water enters nozzle tangentially at top and is given spiral action in spiral chamber.

SPRAY NOZZLES

The performance of cooling tower greatly depends upon the water distribution over the fills. The nozzles distribute water evenly through a wide spray angle without any dry pockets. They are lightweight and reduce the frequency of clogging. The Solid Cone Square Pattern nozzles produce a solid cone spray of water that is Distributed in a square pattern onto the fills.

DRIFT ELIMINATOR

Reduces carry over losses of water. The eliminator is of rigid PVC (Applicable for square type cooling tower). The individual drift eliminators of S-shaped corrugated sheets are bonded with subsequent layers to create the structure. The entire area is thus divided into several fine S shaped mini zones each removing water droplets on the entire surface of the cell.

ALUMINIUM / FRP AXIAL FAN

Specially designed energy efficient fans are of induced-draft axial type with adjustable pitch. Material chosen arenon corrosive of plastic, FRP or aluminium alloy. The high efficiency design ensures low running cost and the lowest possible noise level. Fan blade pitch is factory set and dynamically balanced.

COOLING TOWER MOTOR

The motors are totally enclosed (IP55), flange type, 415 V, 3 ph, 50 Hz, induction weather proof with SS304 extended shaft and are specially designed for cooling tower application.

COOLING TOWER MOTORIZED GEAR BOX

This gearbox series for cooling towers and/or pulp and paper mixers is especially built to grant reliability to customers. This is made possible through a generous upsizing of both gears and bearings as well as a balanced internal gear arrangement, so to offeroptimization of uniformity in balancing loads inside the gearbox. With the half casing the periodic inspection and maintenance purposes are facilitated, especially in places that are not easy to access.

FRP FAN STACK

The aero dynamically designed FRP Fan stack cum recovery cones, FRP Stack velocity recovery cones reduce the discharge pressure the fan has to work against, allowing the fan to move more air for the same energy input. By moving more air though the same unit, the cooling capacity is increased without increasing fan horsepower. Effectively the amount of energy required for each unit of cooling capacity is reduced. A full radius air inlet bell mouth is provided for smooth air flow into the fan. The recovery cone flare angle is designed for velocity recovery of 75% of the difference in velocity pressure at fan level & exit of recovery cone. The fan stack is designed for a wind load equivalent to the design wind load of the cooling tower.

LADDER

The ladder reaches the air outlet, so that it is convenient to maintain the motor and reducer. Each cell of Multi-Cell of cooling tower has a set of ladder.