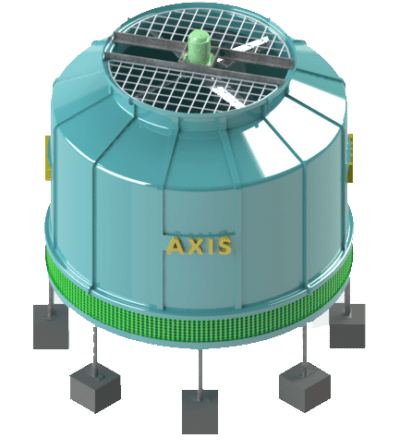

FANLESS COOLING TOWER

Fanless Cooling Tower are nothing but the water is cooled with natural atmospheric air travel and the water is sprayed with the help of Spray nozzles and covered with louvre covers in this cooling tower. This method saves the operating cost of your industry because it has no mechanical fans. These cooling towers are called as atmospheric cooling tower or Fanless cooling tower and filless cooling tower.

KEY CHARACTERISTICS

- The main function of the offered Fanless cooling tower is to cool and maintain the temperature of process hot water at a particular level.

- It is based on the principal of transfer of heat from hot water to atmospheric air by arranging the both air & water to come in contact with each other in such a fashion that heat transfer is maximum.

- The axial flow fans are noise-free. The low speed of the motor minimises noise and increases efficiency.

- Motors are specially designed to withstand moisture, rain and dust.

- This assures better contact of air and water and the high cooling efficiency.

| Draught Type / SHAPE | FLOW TYPE | MOC | CAPACITY TR | FILL TYPE | DRIVE TYPE |

|---|---|---|---|---|---|

| Natural Draft / Rectangle Fanless | Nominal Flow | FRP | 100 – 10,000 | Fill less | Non Drive |

| Louvers | FRP (Isopthalic with Gel Coating) |

| Structural Supports | FRP (Isopthalic Resin with Gel Coating and MS Inserts) |

| Inlet Flanges | Heavy Duty PVC/PP |

| Spray Header | Heavy Duty PVC/PP , 10Kg/cm2 pressure rating(FRP Lined) |

| Drift Eliminators | FRP (Inbuilt in Louvers) |

| Spray Nozzles | 30% Glass Filled Nylon 6 |

| Nut, Bolts & Washers | 30% Glass Filled Nylon 6 and MS Inserts |

PARTS/COMPONENTS

LOUVERS:

Louvers are Horizontal and circular in shape are made of moulded FRP (Fibre reinforced plastic) using isopthalic resin with neopentyl glycol and suitable U.V. Stabilizers. The louvers have in built mist-eliminators to minimize mist losses.

DISTRIBUTION SPRAY SYSTEM:

Made up of thermoplastic pipes reinforced with FRP fitted with thermoplastic (GF Nylon/PP) whirl jet nozzles. The nozzles are self-cleaning, hence no regular Maintenance is required for cleaning. The nozzles feature a center post design That provides long service life and excellent spray pattern uniformity by Precisely controlling the fluid of vertex in the nozzles whirlchamer. Carefully Engineered spray system to assure maximum cooling capacity / cubic foot of Tower volume. Complete utilization of tower area is achieved by locating Specially designed spray nozzles in a pattern determined by test and experience to assure the most effective cooling performance.

STRUCTURAL SUPPORT:

Vertical supports are made of moulded FRP with foundation plates also of FRP having stiffened core for better strength and stability.

JET SPRAY NOZZLE:

The performance of cooling tower greatly depends upon the water distribution over the fills. Nozzles distribute water evenly through a wide spray angle without any dry pockets. They are lightweight and reduce the frequency of clogging. The nozzles produce a solid cone spray of water that is distributed in a square pattern onto the fills..

JET SPRAY NOZZLE:

The performance of cooling tower greatly depends upon the water distribution over the fills. Nozzles distribute water evenly through a wide spray angle without any dry pockets. They are lightweight and reduce the frequency of clogging. The nozzles produce a solid cone spray of water that is distributed in a square pattern onto the fills..

OTHER COOLING TOWER SPARE:

The nutbolts and washer are made of reinforced thermoplastic with main structural bolts of MS-GF Nylon. Therefore all the hardware is of high strength and corrosion free.