Introduction

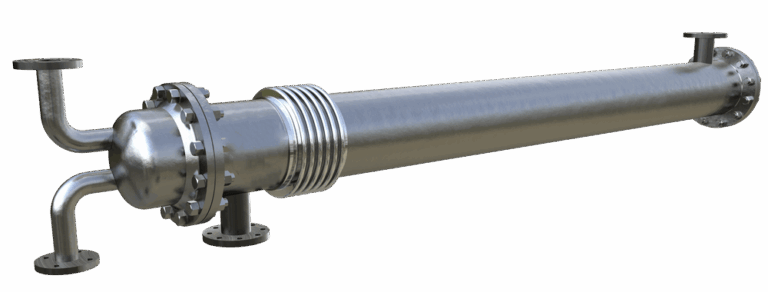

In various industries where heating and cooling processes are essential, heat exchangers play a vital role in transferring heat between two fluids without mixing them. Among different types, the multi-pass industrial heat exchanger is a highly efficient variant designed to optimize heat transfer in systems that demand enhanced thermal performance.

The term “multi-pass” refers to the number of times a fluid passes through the heat exchanger’s tubes or shell before exiting. Unlike single-pass heat exchangers, where fluid flows in one direction only once, multi-pass units force the fluid to change direction multiple times. This design significantly increases the residence time of the fluid in the heat exchanger, enhancing the heat exchange efficiency.

Working Principle of Multi-Pass Heat Exchanger

A multi-pass heat exchanger operates on the principle of indirect heat transfer between two fluids. One fluid flows through a series of tubes (tube side), while the other fluid flows around the tubes (shell side) or between plates (in plate-type exchangers). The multi-pass configuration is achieved by:

- Dividing the flow path using baffles or pass partitions.

- Redirecting the fluid through multiple passes across the heat transfer surface.

- Ensuring greater exposure to the cooling/heating medium for higher efficiency.

In counter-flow arrangements, one fluid flows in the opposite direction of the other, enhancing the temperature gradient and maximizing heat transfer. In parallel-flow, both fluids move in the same direction but are still redirected via multiple internal passages.

Construction Features

A multi-pass industrial heat exchanger typically includes:

- Shell (Outer Casing):

- Holds the shell-side fluid in shell-and-tube types.

- Built to withstand high pressures and temperatures.

- Tube Bundle (Tube Side):

- A group of tubes through which one of the fluids flows.

- Can be U-tube, straight-tube, or serpentine depending on design.

- Baffles or Partition Plates:

- Control the direction of fluid flow inside the shell.

- Force fluids to pass over the tubes multiple times for better heat transfer.

- Front & Rear Headers:

- Serve as entry and exit points for the tube-side fluid.

- Include dividers to separate different passes.

- Tie Rods and Spacers:

- Hold baffles and tubes in position.

- Nozzles/Inlets/Outlets:

- Allow fluid entry and exit on both tube and shell sides.

- Support Plates & Mounting Structures:

- Provide mechanical support to the exchanger.

Advantages of Multi-Pass Industrial Heat Exchangers

- Superior Heat Transfer Efficiency:

- More fluid exposure time increases overall heat exchange between the two mediums.

- Compact and Space-Efficient Design:

- Multi-pass flow allows more heat transfer in a smaller footprint.

- Better Temperature Control:

- Especially useful in systems that require precise thermal regulation.

- Greater Flexibility in Design:

- Passes can be adjusted (2-pass, 4-pass, 6-pass) based on heat duty and flow requirements.

- Enhanced Turbulence:

- Multiple passes create fluid turbulence, improving heat transfer coefficients.

- Cost-Effective for High-Performance Systems:

- Reduces the need for oversized units, saving material and operating costs.

- Customizable Orientation:

- Can be installed vertically or horizontally, based on system layout.

Common Industrial Applications

- Power Plants:

- For turbine oil cooling, steam condensing, and feedwater heating.

- Chemical & Petrochemical Plants:

- Handling corrosive, toxic, or high-temperature fluids.

- Oil Refineries:

- Cooling or heating hydrocarbons, lubricants, or process fluids.

- Pharmaceutical Industry:

- Maintaining process fluid temperatures under sanitary conditions.

- Food & Beverage:

- Heating, cooling, or pasteurizing liquid products.

- Marine Applications:

- Seawater-cooled heat exchangers for engine and gearbox oil.

- HVAC Systems:

- For chilled water cooling, condenser heat rejection, or energy recovery.

Types of Multi-Pass Heat Exchangers

- Shell and Tube Type: Most common industrial design, suitable for high-pressure and high-temperature applications.

- Double Pipe Type: Ideal for small to medium capacity systems; easy to clean and install.

- Plate Type (Gasketed or Brazed): High thermal efficiency, suitable for compact spaces and clean fluids.

Maintenance Practices

- Periodic inspection of tube bundles and baffles.

- Cleaning of fouled tubes to maintain heat transfer performance.

- Checking for corrosion or leakage around gaskets and seals.

- Monitoring inlet and outlet temperatures for system efficiency.

- Pressure testing after maintenance or replacement.

Conclusion

Multi-pass industrial heat exchanger is a cornerstone of modern industrial thermal systems, offering a robust, flexible, and efficient solution for transferring heat between fluids. Its multi-pass configuration significantly enhances the performance by increasing turbulence, residence time, and surface contact, all of which contribute to better thermal exchange.

These heat exchangers serve a vast range of industries—from heavy-duty power generation to sensitive pharmaceutical production—thanks to their versatility, durability, and customizable configurations. Whether used for cooling, heating, condensing, or recovering energy, multi-pass heat exchangers provide reliable and long-term solutions that optimize operational performance and energy usage.

In an age where efficiency and sustainability are paramount, choosing a multi-pass industrial heat exchanger ensures superior thermal control, reduced system downtime, and extended equipment life—making it an essential component of any industrial setup.