vapor to liquid condenser is a critical thermal device used in various industrial systems to transform vapor (gas) into liquid by extracting the latent heat of vaporization. This phase-change process is fundamental to the efficient functioning of refrigeration systems, distillation columns, power generation cycles, and solvent recovery setups. These condensers not only ensure proper temperature and pressure control but also help conserve energy and maintain product quality in closed-loop processes.

Whether it’s recovering valuable solvents in pharmaceutical production, condensing steam in a turbine system, or managing refrigerant flow in an HVAC unit, vapor to liquid condensers play a central role in improving system reliability, performance, and safety. With advancements in material selection and design configurations—from shell and tube to plate-type and air-cooled models—these condensers are now tailored for diverse applications across industries.

Phase Transition Management

A vapor to liquid condenser is designed specifically to manage phase change—the conversion of a vapor (gas) into a liquid—by removing the vapor’s latent heat. This is not just a temperature drop but a change in the physical state, which is critical in systems like refrigeration cycles, steam turbines, and chemical plants. Proper phase transition ensures the efficiency of thermodynamic cycles and reduces vapor losses.

Maximizes Energy Recovery

Condensers often play a dual role in waste heat recovery. When vapor condenses, the latent heat released can be diverted to preheat water, air, or process fluids. This makes the condenser an essential part of energy-saving strategies in industries like power plants (Rankine cycle), refineries, and food processing, where optimizing heat usage leads to reduced operational costs.

Corrosion & Fouling Resistance

Because many vapors—especially in chemical, marine, or food industries—can be corrosive or cause deposits during condensation, these condensers are often built using materials like:

- Stainless steel – for corrosion and temperature resistance

- Titanium – for high chemical compatibility

- Cupronickel or brass – for marine or heat-intensive operations

Additionally, many condensers are designed for easy cleaning or have built-in fouling resistance through smooth tube surfaces or turbulence-inducing inserts.

Critical in Distillation Columns

In fractional distillation, the vapor to liquid condenser (commonly called a reflux condenser) sits at the top of the column. It condenses the rising vapor, and part of the condensed liquid returns to the column to enrich separation through reflux. This is essential for precise separation of substances based on boiling points in petrochemical refining, alcohol production, and pharmaceutical synthesis.

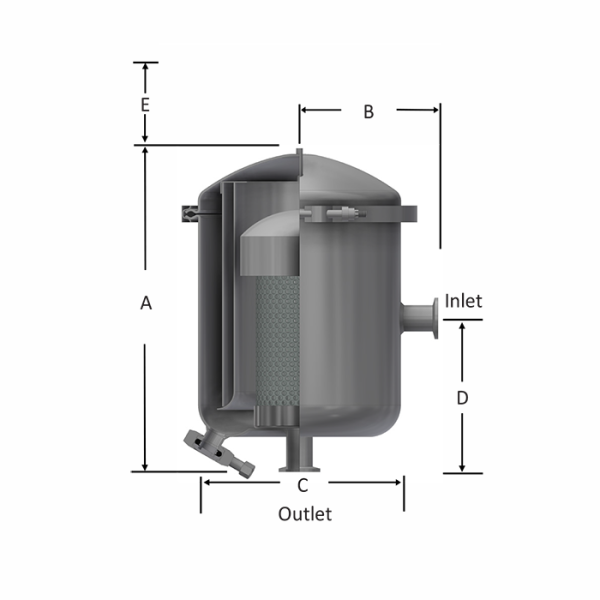

Available in Multiple Designs

Vapor to liquid condensers are not one-size-fits-all. They are available in:

- Shell and Tube Condensers: Ideal for large industrial capacities.

- Air-Cooled Condensers: Use ambient air instead of water—good for dry or remote locations.

- Plate-Type Condensers: Compact, efficient, and commonly used in HVAC and food processing.

- Fin and Tube Condensers: Boost heat transfer in small-scale or portable systems.

Design choice depends on heat load, type of vapor, space, and cooling medium.

Supports Environmental Compliance

Many industries generate vapors that are harmful or regulated, such as volatile organic compounds (VOCs), hydrocarbons, or alcohols. Vapor to liquid condensers enable the recovery and reuse of these vapors, preventing them from being vented into the atmosphere. This aids in meeting environmental regulations (e.g., EPA, CPCB) and supports green manufacturing goals.

Conclusion

Vapor to liquid condenser serves this exact purpose by enabling precise thermal management, conserving energy, reducing emissions, and enhancing process stability. In any system where vapor is generated, controlling and converting that vapor back into liquid form is not only necessary but also vital for operational efficiency and safety.

From high-efficiency industrial distillation to clean vapor capture in green technologies, these condensers ensure that valuable vapors are recovered, process cycles are completed, and environmental standards are upheld. With the right material, size, and design, they can handle volatile fluids, corrosive substances, and demanding thermal conditions—making them an indispensable component in both modern industry and sustainable operations.