Introduction

Welded Plate Heat Exchangers represent one of the most advanced heat exchange technologies available today, designed to provide highly efficient thermal transfer solutions for a wide range of industrial applications. Unlike gasketed plate heat exchangers, which use gaskets to seal the plates, WPHEs are constructed using welded plates, making them ideal for high-pressure, high-temperature, and aggressive fluid handling. These heat exchangers are designed to handle fluids that are corrosive, toxic, or involve a high risk of leakage, making them highly sought after in industries that require robust performance under demanding conditions. The design of WPHEs also makes them compact, highly efficient, and able to provide superior heat transfer even in environments where space is limited.

Construction and Design

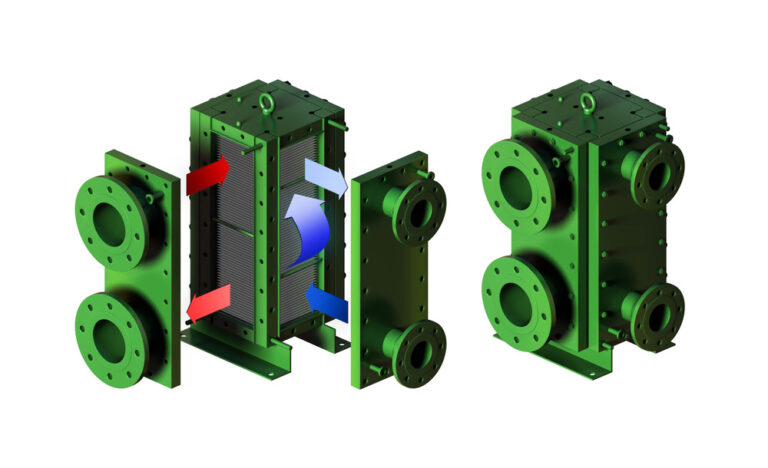

The construction of a welded plate heat exchanger involves several key components:

- Welded Plates: These are the primary heat transfer elements. The plates have a corrugated design, which increases the surface area and induces turbulence in the fluid flow, improving heat transfer efficiency. These plates are welded together along the edges to form a durable, leak-proof unit, eliminating the need for gaskets. Welding can be done using various techniques, including laser welding and TIG welding, to ensure a strong bond.

- Plate Pack: The plates are stacked together to form the plate pack. This pack is what carries the fluid on both the hot and cold sides, ensuring the heat transfer between the two. The plate pack is enclosed within a frame, which is usually made of carbon steel or stainless steel.

- Inlet and Outlet Connections: Each side of the unit is equipped with inlet and outlet ports where hot and cold fluids enter and exit. These are designed to handle high-pressure conditions.

- Frame and Shell: The frame is designed to hold the entire stack of plates in place, ensuring structural integrity and minimizing vibration. In some designs, a shell can be used to enclose the plates to further protect them.

This robust construction ensures that the WPHE can withstand extreme operating conditions, providing a long service life and reliable performance even in challenging environments.

Working Principle

The working principle of a welded plate heat exchanger is based on the same fundamental idea as any other heat exchanger — transferring heat from one medium to another. In a WPHE:

- Hot and cold fluids are passed through separate channels formed between the plates. The plates themselves are the heat transfer surface that facilitates the thermal exchange between the fluids.

- The corrugated design of the plates creates a turbulent flow that increases the heat transfer coefficient, allowing for more efficient heat exchange between the fluids.

- The welded plate construction means that the exchanger is leak-proof and can operate at higher pressures and temperatures than gasketed plate heat exchangers, making it ideal for applications with aggressive or hazardous fluids.

The heat transfer process works as follows:

- The hot fluid transfers its heat through the plates to the cold fluid, which absorbs the heat and increases in temperature.

- Due to the thin, high-conductivity metal plates, the heat transfer is maximized, allowing for highly efficient heat exchange.

Key Advantages

High Heat Transfer Efficiency

- The corrugated plates induce turbulence, which maximizes heat transfer by increasing the surface area for contact between the fluid and the metal. This allows for higher heat transfer rates compared to traditional shell-and-tube designs.

- The compact design of WPHEs means that even with a small footprint, these heat exchangers can provide equivalent or even better performance than bulkier systems.

Compact Footprint

- One of the most significant advantages of welded plate heat exchangers is their compact size. These heat exchangers can handle a large heat exchange capacity within a very limited space, making them ideal for applications where space is limited.

- In industrial settings, this compactness translates to lower installation costs and less real estate required in a plant or facility.

Leak-Free, High-Pressure Handling

- The fact that the plates are welded together means there is no risk of leaks at the plate joints, which is a major advantage in applications where fluid safety is a priority.

- WPHEs are designed to withstand high-pressure conditions, with some models able to handle pressures up to 60 bar (870 psi), making them ideal for industries where high-pressure systems are common, such as chemical processing, oil & gas, and petrochemical industries.

Durable and Low Maintenance

- WPHEs have fewer gasketed connections than their gasketed counterparts, which reduces the chances of leakage and the need for routine maintenance like gasket replacement.

- The welded design makes them highly resistant to mechanical stresses, vibration, and pressure cycling, which can degrade other types of heat exchangers over time.

- They are highly resistant to fouling, reducing maintenance requirements and enhancing their reliability over extended service periods.

Customizable Flow Configurations

- WPHEs can be designed to accommodate different flow configurations to suit the specific needs of the application:

- Counter-current flow: The most efficient design, where fluids flow in opposite directions, maximizing heat exchange.

- Parallel flow: Fluids flow in the same direction, which is less efficient but useful for certain applications.

- Crossflow: Fluids flow perpendicular to each other, useful in specific applications like HVAC systems.

Limitations

While WPHEs offer numerous benefits, there are certain limitations to consider:

- Difficult to Clean Mechanically: Due to the welded design, cleaning the internal surfaces of the heat exchanger can be more challenging compared to gasketed models, especially when fouling or scaling occurs. Cleaning often requires specialized procedures or disassembling the unit, which can lead to higher maintenance costs.

- Higher Upfront Cost: WPHEs generally have a higher initial cost compared to gasketed plate heat exchangers due to the complexity of welding and the materials involved. However, the long-term savings from reduced maintenance and better performance can offset these costs over time.

- Repair Difficulties: If a plate or part of the heat exchanger fails, it is not as easy to repair as gasketed designs. In some cases, re-welding may be required, which is a highly specialized process.

Types of Welded Plate Heat Exchangers

Fully Welded Plate Heat Exchanger

- The most common type of WPHE, where every plate is welded together to create a leak-proof structure. This design is ideal for highly corrosive or hazardous fluids that require a strong, durable system to handle high pressures and temperatures.

Shell & Plate Heat Exchanger

- This design features a welded plate pack enclosed in a cylindrical shell. It provides extra protection to the plate pack and can be used in applications requiring additional strength to handle vacuum, pressure, or temperature extremes.

Brazed Plate Heat Exchanger (BPHE)

- Smaller than traditional welded models, brazed units are ideal for moderate applications like HVAC systems and small industrial applications. The plates are brazed together using copper or nickel, providing a cost-effective and compact solution.

Semi-Welded Plate Heat Exchanger

- This type has pairs of plates welded together, and the rest of the plates use gaskets. This allows one side of the heat exchanger to be cleaned while keeping the other side welded for extra durability. Semi-welded units offer a balance of maintainability and robustness.

Conclusion

Welded Plate Heat Exchangers provide a superior solution for industries dealing with high pressures, high temperatures, and aggressive fluids. Their high heat transfer efficiency, compact design, and leak-proof construction make them the preferred choice in sectors like chemical, petrochemical, and oil & gas. Although their initial cost and maintenance requirements may be higher compared to traditional heat exchangers, their long-term reliability, energy savings, and efficiency make them a smart investment. As industries continue to evolve toward more sustainable, space-saving solutions, WPHEs will remain a cornerstone of industrial thermal management.